1 min read

Improved Lumber Recovery at New Southern Yellow Pine Sawmills

Roy Anderson : March 18, 2019

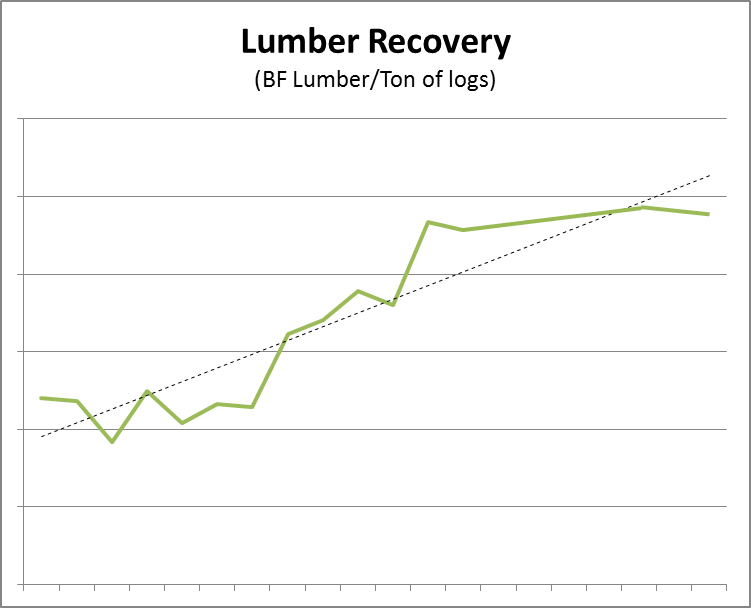

Technological advancements in log scanning and positioning relative to saws have led to the steady improvement in lumber recovery (yield) at southern yellow pine (SYP) sawmills over time. While the upward trend slowed when capital spending slowed dramatically during the industry’s lean years (2007-2011), we should expect the latest round of investments in new and upgraded mills to provide another jolt of improved yield levels for the SYP industry.

What will be the primary sources of recovery improvement at new mills? The Beck Group has identified three primary areas where new and upgraded sawmills are likely to be advantaged:

- High-resolution scanning and optimization – Older scanning head models scanned a log, or piece of lumber, in relatively coarse intervals (say, every 6”). The resulting optimizer solutions were an improvement in speed and accuracy compared to the judgment of human operators. Over time, however, as computing power and scanning technology has improved, optimizers have moved to higher and higher resolution scanning and optimization that produces incrementally more accurate sawing solutions for machines throughout the sawmill. We can expect the newest SYP mills to incorporate the latest generation of scanning and optimization with some machines utilizing extremely high resolution images (photo quality) while simultaneously delivering faster and more accurate sawing decisions.

- Optimized log rotation – While this is not a new technology, many saw lines at SYP mills have manual log rotation or early versions of automated log rotation. We should expect nearly all of the newly installed primary breakdown lines to have high-resolution scanning and computer-optimized log rotation. This will result in a more accurate placement of the log or board in the position relative to the saws that will yield the optimal combination of lumber value and volume.

- Optimized log bucking – Loblolly pine logs are notorious for having more sweep and crook than other commercialized softwood lumber species. Curve sawing and computer-optimized log bucking are two technologies that help to reduce the negative impacts of log curvature on lumber recovery. While the vast majority of SYP sawmills adopted curve sawing gang edgers during the 1990s and 2000s, far fewer mills installed optimized log bucking because the payback for replacing existing systems was often not as attractive as other capital projects. However, we can expect that the new mills being built across the southern yellow pine region will take advantage of both the yield improvement and the higher production speeds that the latest generation of optimized bucking lines has to offer.