Sawmill owners and managers are continually striving to maximize the profit made from each log purchased in order to outcompete other sawmills. A simple prescription for this is to keep raw material costs as low as possible while maximizing sales; it’s manufacturing 101, but as the old saying goes, “it’s easier said than done.”

As I discussed in a previous post, the best-in-class dimension lumber mills around the US South run the ideal log size for their particular mill and equipment setup, and they proactively work to buy that sized log on the market. After determining the ideal log size, mills must then identify the maximum price that can be paid for these logs in order to operate efficiently and profitably. Since log cost is by far the largest operating cost for a sawmill (70-75 percent), resourceful log procurement is imperative. A common calculation top-tier mills use when evaluating the amount they can pay for logs is derived through a break-even analysis or return to log (RTL) calculation. An RTL calculation, in very general terms, is an effective way for sawmills to determine the value of a log based on the products that can be produced from that log minus the cost of production:

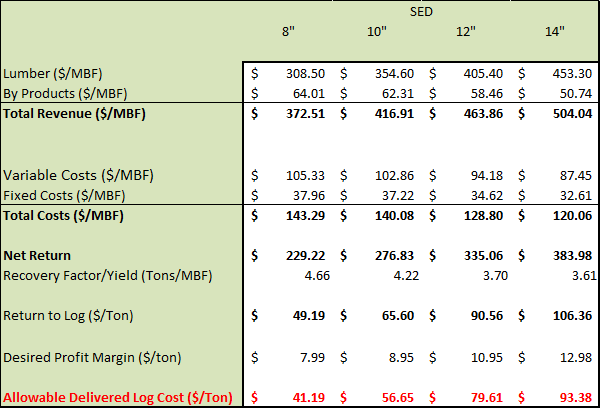

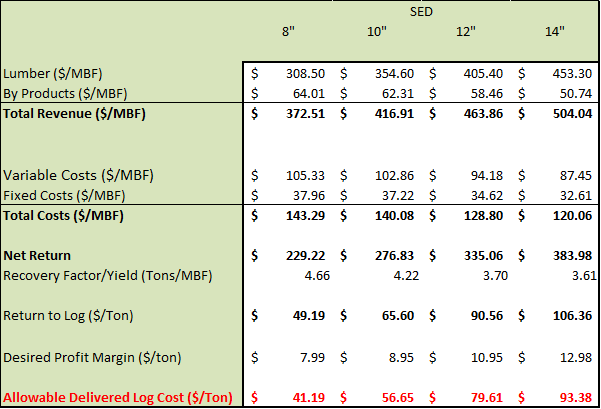

Total Revenue ($/MBF)

– Total Cost ($/MBF)

Drivers in RTL calculations

A number of factors go into the above calculation and determine the value of a log from the mill’s point of view. The first consideration is the potential revenue that each log can generate:

- Total revenue resulting from the sale of numerous products:

- Finished products (lumber)

- By-products

- Residual chips

- Shavings

- Sawdust

- Bark/hog fuel

Aside from the already high raw material cost, there are additional variable and fixed costs associated with the manufacturing process:

- Variable Costs

- Log cost

- Log yard (inventory) cost

- Sawmill operating costs

- Labor

- Drying

- Planing

- Shipping

- Maintenance cost

- Fixed Costs

- General & administrative costs

- Log procurement (staff)

- Sales (Staff)

- Depreciation

- Interest

- Corporate fees

Basic Example of RTL Calculation:

While a mill’s RTL calculations aid in determining what can be paid for each size log, it doesn’t provide insight into what price should be paid to maximize profit. Once mill managers have a sound understanding of log value to their individual mills, they can then take the next step of comparing the individual value of a log versus how the market values that log. While logs may be worth one price to a given sawmill, the market may command a different price.

Forest2Market tracks pricing data on logs at both purchase points in the raw material supply chain: the landowner (stumpage) and at the mill gate (delivered). Because Forest2Market collects transaction level data and captures log size with each transaction, this allows mill managers access to accurate and precise market data on all log sizes to use in conjunction with their internal RTL calculations.

When a mill’s internal data is combined with Forest2Market’s market pricing by log size, a mill’s procurement staff can begin to fine tune its procurement strategy. This process will increase the mill’s profit margin by aiding in the procurement of the most profitable log while buying that log at the lowest market price. For example, once a procurement team understands what each log in their profile is worth, as well as the market price for these logs, they can begin to build a log valuation sheet.

As shown in the basic example above, the end result of the RTL calculation is the maximum delivered price a mill can pay for a specific log size while accounting for the costs associated with manufacturing and day-to-day operations. Procurement foresters can take this information and then negotiate prices with suppliers based on both aspects: what the mill can pay, and what the market value is for a certain log. They can also use this information to determine the maximum stumpage price they can pay a landowner after harvesting and freight costs are considered.

Many mills across the country have been implementing these calculations for quite some time, but as lumber markets have curtailed production and margins have become thinner in the wake of the Great Recession, these types of evaluations are becoming more prevalent. Comprehensive analyses of a mill’s revenue/costs based on detailed log sizes and accurate market data will help management teams develop log procurement strategies that will increase profitability and long-term success.

Joe Clark

Joe Clark