3 min read

Escalating Pressure for European WFU Producers Raises Essential Questions

Fisher International

:

May 4, 2021

The ground continues to shift across the EU as demand patterns in the woodfree uncoated (WFU) segment have driven manufacturers to make some difficult decisions. Most recently, Stora Enso announced the permanent closure of two facilities operating in the WFU, mechanical grades and newsprint segments in Finland and Sweden. Pulp and paper production at the two facilities is scheduled to cease in 3Q2021.

The planned closures will reduce Stora Enso’s paper production capacity by 35% to 2.6 million tonnes per year (tpy) and come at a time when EU manufacturers are forced to match production to the declining demand trends that have accelerated during the COVID-19 pandemic.

Per FisherSolve, the Veitsiluoto mill in Kemi, Finland has a total capacity of 732,420 MTPY via three paper machines; two machines produce WFU papers for office use and one machine produces coated paper grades for other print and packaging applications. Additionally, the mill has an integrated chemical pulp mill (414,000 ADMTPY), groundwood mill and a sheeting plant, as well as a functional sawmill. The planned closure of the site will impact all business segments aside from the sawmill, which will continue operations.

The Kvarnsveden mill in Borlänge, Sweden has two paper machines with a total capacity of 550,000 MTPY of supercalendered (SC) magazine papers and improved newsprint. The mill also has an integrated softwood thermomechanical pulp (TMP) line with a total capacity of 368,340 ADMTPY.

What impacts will this reduction in capacity have across the region?

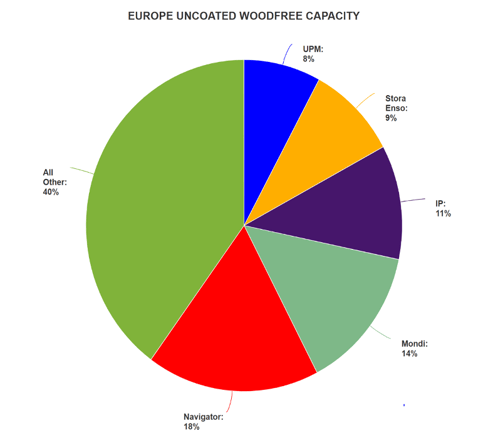

Total WFU capacity across the EU in 4Q2020 was approximately 7,900,000 MTPY. While Stora will continue producing WFU papers at its Nymölla mill in southern Sweden, the Veitsiluoto closure will result in a capacity reduction in the EU of more than 6% to 7,400,000 MTPY. A double-digit decrease in capacity seems sudden and significant, but it is likely not enough based on plummeting demand patterns for this grade.

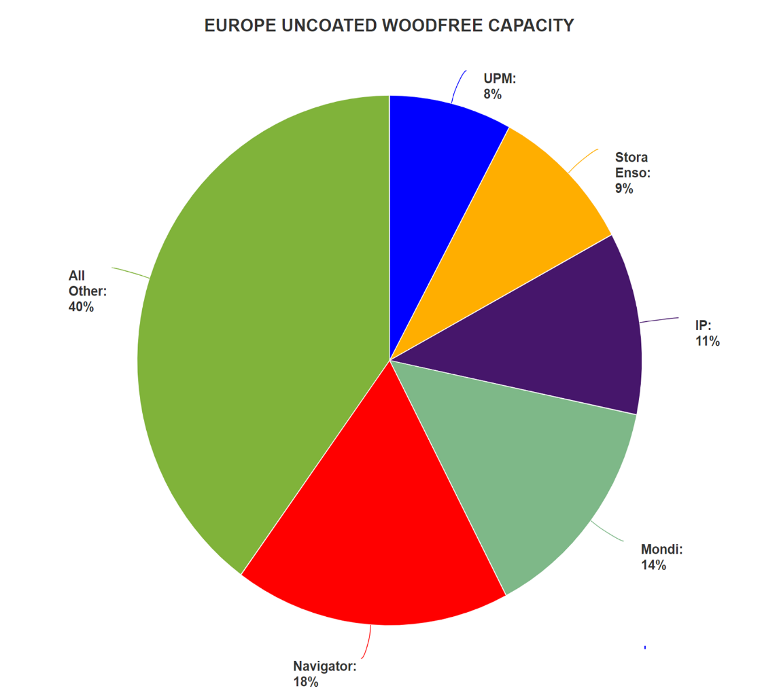

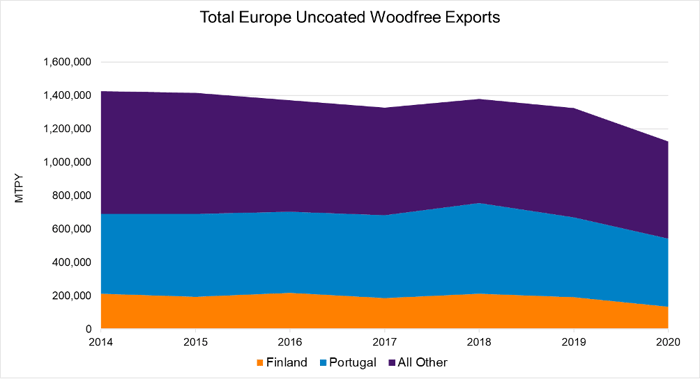

European WFU production is highly fragmented; no single producer maintains a strong enough position to disproportionately influence market pricing. In such an environment, publicly-held companies with quarterly earnings targets and greater production elasticity are often first to react to market signals and reduce volumes.

Source: FisherSolveTM Next 2021 Fisher International, Inc.

We have witnessed a global change in copy paper consumption develop over the last 20 years as widespread access to the internet has ushered in a new digital age—a profound shift in accessibility, information gathering and knowledge sharing that is still developing at an ever-quickening pace. As a result, demand for printing and writing papers continues to decline as the digital age matures. However, the closure of offices and schools across the globe during the COVID-induced lockdowns has driven an accelerated demand destruction of this segment.

Source: European Association of Graphic Paper Producers, 2021

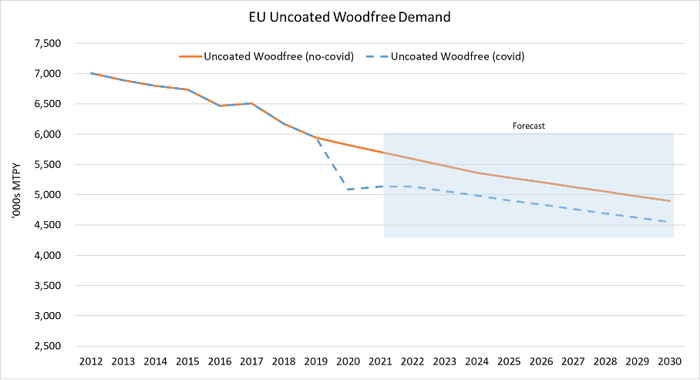

Despite the large gap that currently exists between WFU demand and production capacity in the EU, this grade was relatively healthy before the pandemic. European export volumes and prices were very strong in 2018, which was driven by robust demand from North Africa, North America and the Middle East. However, with EU consumption now declining in a post-pandemic economy defined by increased uncertainty, exports are likely to taper as protectionist sentiments become more pervasive.

Source: FisherSolveTM Next 2021 Fisher International, Inc.

Though Stora Enso’s recent move seems reactionary on the surface, the data suggest that further capacity reductions are still needed to better match updated demand patterns to production volumes.

What mills are at risk during this transition?

While this development raises a number of questions, we can use business data, tools, and models to define likely scenarios moving forward. Production costs, asset health, logistics and profitability concerns will define “next steps” for manufacturers who commit to the changing dynamics of this segment. Should pandemic-related restrictions ease enough to allow a slow reopening across the EU, there will at least be a short-term increase in demand as businesses and schools resume previous patterns. That said, producers expecting a widespread return to pre-2019 activity will be disappointed.

Key questions major players need to be asking in the wake of Stora’s announcement:

- Will this change make it more difficult for producers to service Europe cost effectively?

- Will exports decrease as a natural reaction to capacity adjustments? Will this benefit producers in other regions an if so, which producers will benefit?

- Who will be the “last men standing?” Which large, EU producers will consolidate WFU market share as competitors decide to exit the category?

- Will there be enough consolidation to encourage the surviving companies to invest in the future?

- Russian producers have a real cost advantage in this segment. The drop in Russian demand has not been as severe as the EU, which provides them an advantage in this segment. Can Russian producers capture market share as EU producers drop off?

Cost benchmarking is an accurate tool to help manufacturers answer some of these questions and better understand their competitive positions. However, in the current WFU market across the EU, cost benchmarking doesn’t provide a full-spectrum view for maximizing strategic decision making; producers need to understand all the factors predictive of longer-term asset performance. In the next segment of this two-part series, we will look at Fisher’s viability benchmarking and forecasting tools and how they can help European WFU producers audit their current assets and positions to chart a smarter way forward in this dynamic market.