2 min read

New Arena Highlights Mass Timber Functionality Using Local Forest Resources

John Greene

:

October 21, 2021

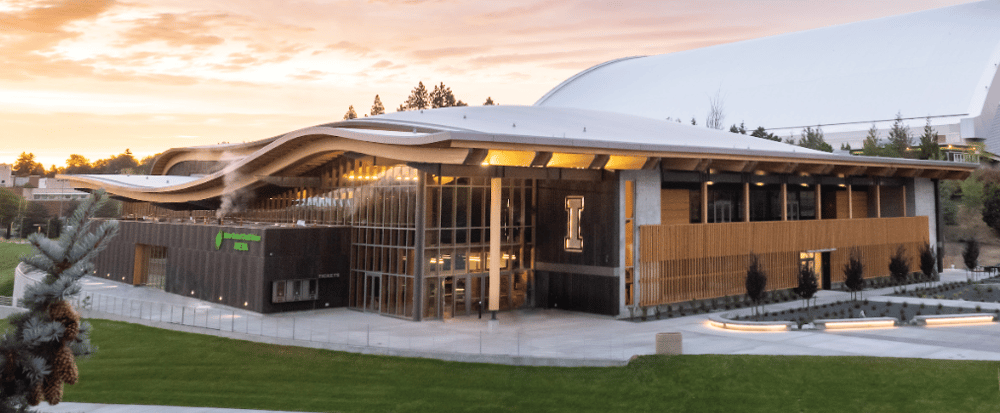

The University of Idaho recently unveiled its new 4,200 seat arena that brings stylish, functional design to life with the help of local timber resources. The recently completed 62,000-square-foot Idaho Central Credit Union Arena was constructed using over 800 Douglas fir mass timber beams. The facility overlooks the University’s Moscow campus and is home to the school’s men’s and women’s basketball teams.

The building also highlights the region’s vibrant forest sector and wood products industry, just in time for National Forest Products Week 2021.

As The Spokesman-Review noted, “The new building is in partnership with Idaho’s timber industry and highlights what the industry can do with mass-timber construction. Boise Cascade, PotlatchDeltic, QB Corp, Idaho Forestry Group and Tri-Pro Cedar Products all had a role in acquiring timber, fabricating the beams and transporting them and the accompanying wood appointments throughout the arena to Moscow.”

The $51 million arena was also made possible in part by the U.S. Department of Agriculture, (USDA) Forest Service Wood Innovations Grants program. This funding supports traditional wood utilization projects, expands wood energy markets, and promotes using wood as a construction material in commercial buildings.

“The Wood Innovations funding (from the Forest Service) enabled us to engage architectural firms early on and really nail down the proof of concept that would define how the project would proceed. Showcasing the potential of mass timber and relying on local wood supply were priorities for us,” said Dennis Becker, Dean of the University of Idaho’s College of Natural Resources.

“Fast Facts” per the USFS:

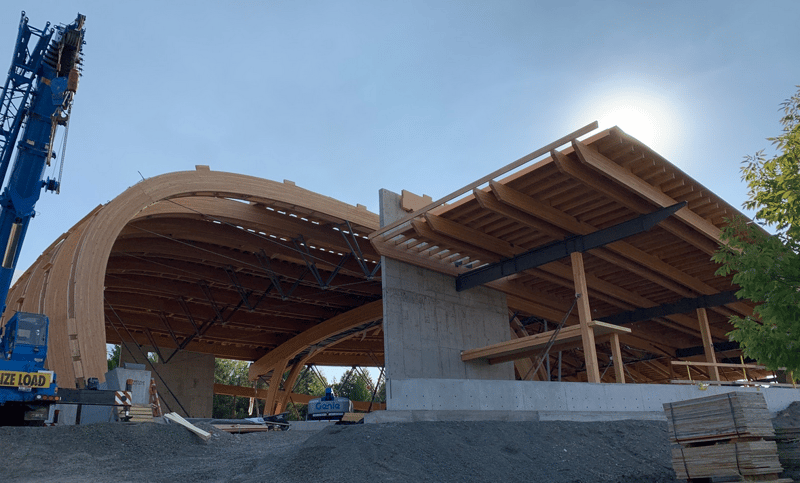

- The main roof beams and purlins (which support the rafters) weigh a combined 442 tons and span 130 feet over the main court.

- The $51 million arena used wood sourced from Idaho.

- Idaho’s $2.4 billion forest sector came together to support the project with donated materials, expertise, and the use of their fabrication facilities.

- USFS Wood Innovations funding enabled engaging architecture firms and State building code specialists early on to nail down the proof of concept.

Photo courtesy of University of Idaho

Photo courtesy of University of Idaho

What Exactly is Mass Timber?

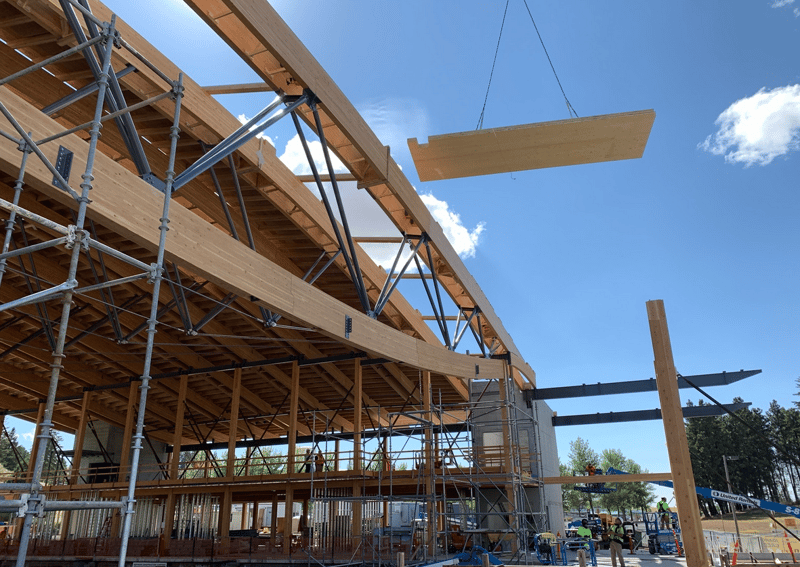

Mass timber and cross-laminated timber (CLT) are panelized structural engineered wood products that can be used in all major building components (floors, interior and exterior walls, and roofs). These products can also used as ground matting at construction and mining sites, allowing heavy equipment to operate on unstable soil.

CLT is made of three or more layers of lumber, each layer oriented perpendicular to the adjacent layer. The layers are then pressed together and bonded with a special adhesive. The lumber is typically pre-selected so major defects (knots, checks, etc.) are removed prior to lay-up. CLT panels used for building construction are commonly 8 feet - 12 feet in width, 20 feet - 60 feet in length, and in 3.5 inches - 9 inches in thickness. Panel length is limited only by press size and highway trucking regulations.

Photo courtesy of StructureCraft Builders

Photo courtesy of StructureCraft Builders

Photo courtesy of StructureCraft Builders

Photo courtesy of StructureCraft Builders

Because the lumber is layered with alternating grain orientation, the strength, dimensional stability, and fire resistance of CLT panels are significantly greater than for individual boards. Many CLT panels are customized for a specific construction project, meaning the exact width, length, thickness (and arrangement of layers), and other properties of each panel are tailored to one building. Openings for doors and windows, as well as openings or channels for electrical, plumbing, and HVAC, are commonly pre-planned and cut by the manufacturer using CNC routers. The prefabricated panels therefore minimize the labor needed at the construction site and dramatically speed construction.

To learn more about CLT and mass timber, check out the 2021 North American Mass Timber State of the Industry Report.